The Rio Tinto Fer et Titane (RTFT) P84 dry tailings stack is located near RTFT facilities in Sorel, Québec. The site operates in conjunction with the iron and titanium benefaction plant. The tailings are a by-product of the benefaction processes at the site. The tailings are transported “dry” by rail to the P84 dry stack area.

A portion of the site has already been remediated whereas another portion of the site is currently active and undergoing a vertical expansion.

The site is in constant change dues to ongoing operations and continuous improvement by the owner and design engineers. In order to further reduce risk, the team has decided to upgrade the current manual data collection of water levels from water level sensors in open standpipes to an automated system. It is expected that additional instrumentation will be added over time and the owner would also like to collect data from other nearby instrumented infrastructure. With this in mind, the selected remote instrumentation monitoring system was chosen for future expansion and compatibility.

GKM Consultants (GKM) provided the following services to the owner’s team.

1. Researched the most appropriate system considering existing compatibility and future expansion requirements.

2. Converted the existing manually read observation wells with automated acquisition devices. Loadsensing data loggers were used to collect the data remotely. This system transmits data over hundreds of meters with minimal maintenance

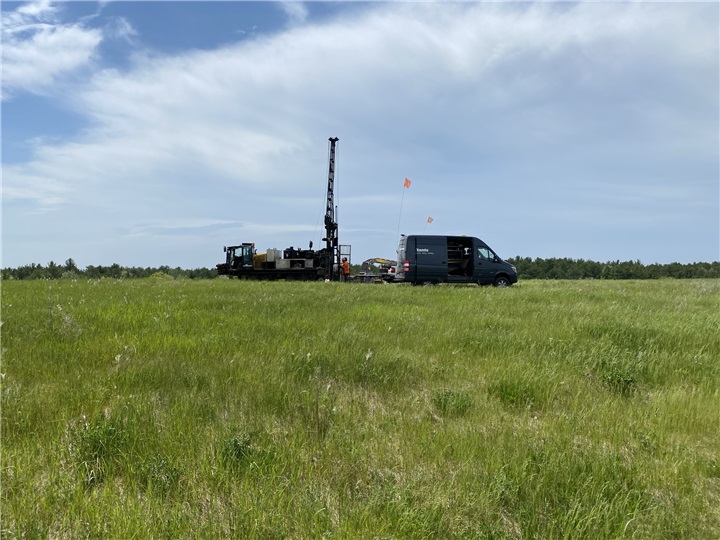

3. Completed the drilling, geotechnical in-situ testing and sampling, and the installation of new sealed vibrating wire piezometers.

4. Provided the initial set-up of the Remote data management system (RDMS) including dashboards, reports, alarm levels, and users. Online tools complement the fully automated hardware, opening the possibility of real-time reporting as opposed to the occasional manual reporting.

5. The GKM Consultants data science service (DSS) cleaned, verified, and integrated all historical data for the site into the database.

6. Provided the appropriate training to the owner’s team.

GKM is proud to be part of the risk management solution selected by Rio Tinto for their P84 tailings dry stack.