CHALLENGE

Mining operations tend to produce large amounts of tailings. In Quebec, and northern Canada, mine operators are required to ensure the sites containing tailings are restored, which can take a long time. And while it is happening, the sites need to be monitored to ensure nothing goes wrong. That was the case with one large zinc mining concern that acquired two old tailings storage facilities as part of the purchase of assets from another company.

The facilities are remote, with one located an hour’s drive from the nearest population center and the other around three times further away. And because they belong to mines that are no longer operational, there is no employee nearby to monitor them. Given mounting concerns and growing regulation around the safety of tailings facilities, the mining company involved was keen to install monitoring systems that could track the integrity of the infrastructures with high accuracy around the year.

SOLUTION

The mining company had an engineering contractor evaluate the risks from the tailings facilities, and the contractor’s advice was to monitor the sites remotely. This led to the mining company’s monitoring consultant, GKM Consultants, implementing a structural health monitoring program integrating existing instrumentation with new sensors to track the physical and chemical stability of the sites.

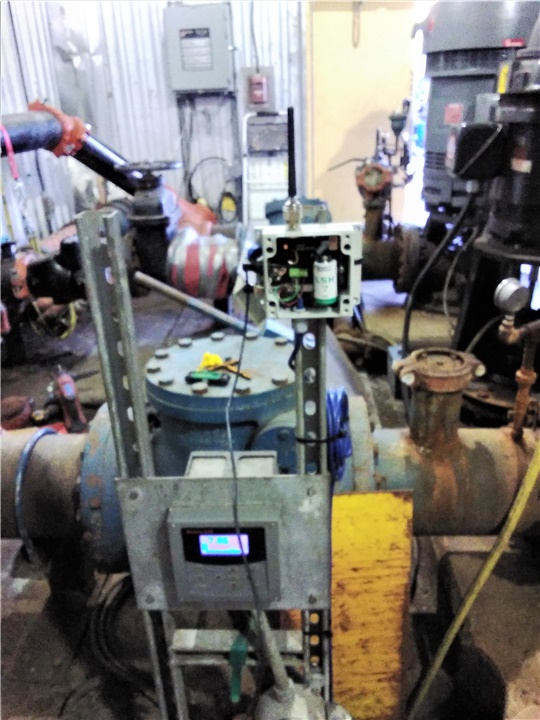

For physical stability, GKM chose to install around 60 vibrating wire piezometers across both sites, and six Worldsensing tiltmeters to monitor stresses on one retaining wall affected by reservoir ice.

There are also plans to deploy Measurand ShapeArrays with digital nodes in the future. To measure chemical leakage, the project employs a pH meter attached to a Worldsensing analog node.

BENEFITS

The Worldsensing equipment’s low power requirements mean the data loggers can operate in the field for several years without new batteries, resulting in low maintenance costs. Costs are further reduced by the quality of the equipment, which results in few failures.

Furthermore, a radio range of up to 10 kilometers means there is little need for repeaters and data can be collected from across a site using a single gateway. Finally, the Worldsensing data loggers can work alongside a wide range of sensor types and products.

The equipment allows the mining operator to prove that it is complying with Quebec’s strict environmental regulations, which is a prerequisite for obtaining insurance and finance.

Going forward, the mining company hopes to monitor the integrity of its tailings facility coverings using agricultural instruments to measure soil water content and soil matrix suction potential. This is a novel area for remote monitoring, but one that Worldsensing can handle.

ADVANTAGES

- Automated data logging removes the potential for manual transcription errors and individual differences in reading

- Round-the-year operation means readings can be taken at times when access to the sites would be difficult

- Remote readings reduce the need for site visits and investment in human resources

“It was a slam dunk for us because we were familiar with the other technologies and nothing else could do it. For this site, it was a no-brainer.”

John Lemieux, Eng., Business Development Manager, GKM Consultants

.jpg)

_01.jpg)